Commercial Ice Machines

Undercounter Ice Machines

Combining the power of an ice machine head and ice storage bin into one compact unit, these units are designed to fit under standard countertops and can make and store a variety of ice types.

Shop 4 Categories >>Ice Machine Heads

Create fresh cube, nugget, or flake ice in large volumes for any commercial environment. Get the ice volume your commercial kitchen needs, with easy-to-clean componants.

Shop 3 Categories >>Ice Storage Bins

While ice machine heads make the ice, ice storage bins keep it frozen and ready to serve. The insulation of an ice bin keeps your ice cold for hours.

Shop 4 Categories >>Ice Machines Parts & Accessories

Repair and maintain your ice machine with our selection of high-quality parts, kits, and accessories. Find reliable components and easy-to-install options.

Shop 4 Categories >>

100% Parts & Labor Coverage

Protect your equipment with a $0 deductible extended warranty from CPS.

Learn more about CPS warranty >>Popular Products

Commercial ice machines come in many difference shapes and styles to suit your individual business needs.

The importance of ice in any commercial foodservice business cannot be overstated. Ice is used in everything from drinks to cold food displays. Ensuring that your ice maker is in top working condition and is the right one for your needs is essential. We have all the resources you need to make the right decision, but you can always speak to one of our expert sales representatives if you have any questions! Ice machines are essential for bars, restaurants, grocery and convenience stores, hotels, and so much more. Whether you need a unit to have a small amount of ice for display purposes or for a constant flow of drinks all day, Burkett has the right ice machine at the right price just for you.

Frequently Asked Questions About Commercial Ice Machines

What are the different types of commercial ice machines?

- Ice machine heads - modular ice machine heads are the gold standard of commercial ice machine production. They require a separate bin or dispenser for the ice to go after it’s made, but they have the highest volume production compared to any other type of ice machine. These industrial ice machines sit on top of their dispenser, bin, or soda machine and allow ice to be ready to keep up with demand in any high volume environment.

- Ice machines with dispensers - ice machines with dispensers are smaller, typically countertop units. They have a much lower volume production rate, and can dispense ice with the push of a button, as well as water in select units. They are best used in compact, self-serve environments.

- Ice storage bins and dispensers - when choosing a modular unit, you have a large range of options for your ice machine head to dispense into. Ice storage bins and dispensers are available in a multitude of styles and sizes to perfectly suit the needs of any environment, from bins for back of the house use in restaurants to self-serve hotel ice dispensers. There are also other storage bin options that require manual refilling from a separate ice machine such as:

- Drop-in ice bins - fit in any countertop or bar that keep ice frozen and available in a convenient location

- Ice and water stations - similar to drop-in ice bins but also include a water dispenser

- Mobile ice bins - can be used in catering or outdoor events to keep ice that was made in a separate location frozen anywhere you need it.

Do I want an air cooled or water cooled commercial ice machine?

The answer to which type of ice machine cooling you need depends on a few factors about where you plan to place the ice machine.

- Air cooled ice machines are more popular than water cooled as they are cheaper to run and more energy efficient. They are best used in well-ventilated areas with lower temperatures. If the air that comes into the unit has poor ventilation or is too hot, it can run harder and slow down production.

- Water cooled ice machines are more expensive to operate as they require a larger water intake (about 5 times more than an air-cooled ice machine). Despite this, water cooled ice machines can be a better choice in compact environments with little ventilation space or hot kitchens.

Do I want a modular or self-contained commercial ice machine?

Modular ice machines (ice machine heads) make ice to be directly supplied to a separate ice machine bin, ice dispenser, or soda machine.

- Pros: they are versatile and can be swapped out easily between different dispensers or bins. Ice machine heads can produce significantly more ice than a self-contained unit.

- Cons: they take up more space due to needing a separate bin/dispenser and require an additional electrical and plumbing hookup for each piece.

Self-contained ice machines make and store/dispense ice all in the same unit. They come in various styles such as undercounter and countertop. Self-contained units are best for lower volume establishments with less space.

- Pros: they are much more compact and require less space, fitting underneath a counter or on top of one. They also only require a single electrical and plumbing hookup, as it is all one unit.

- Cons: the production is much smaller and cannot keep up with the demand of larger establishments. You also cannot change the bin/dispenser size without replacing the entire unit.

What are the different types of ice?

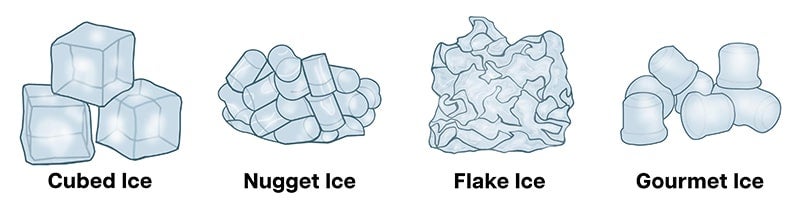

There are 4 standard types of ice available in a commercial ice machine - cube, nugget, flake, and gourmet.

Cubed ice is the standard for beverages. The cubes can be half or full sized dice, but any style of ice cubes is great for all types of drinks.

Nugget ice, also called chewable ice or “Sonic ice,” was originally designed for healthcare use but has become extremely popular in fast food, convenience stores, and many other businesses’ beverage service.

Flake ice is perfect for displays, such as meat and seafood cases, buffets, cafeterias, delis, and other similar uses. It can also be used for blended drinks.

Gourmet ice is used by high-end bars to add a signature touch to any drink. The larger surface area of gourmet ice cubes can keep the drink from becoming watered down, ensuring the flavor keeps its integrity while still at the optimal temperature.

How do I know what size commercial ice machine I need?

Commercial ice makers are sized by how much ice they can produce in a standard 24 hour cycle. Since ice makers last for around 10 years (when taken care of properly), always consider potential growth when figuring out how much ice your business needs.

To determine your business’s ice requirements, you will need two pieces of information: business type and average customers per day.

- Restaurant: 1.5 lbs. of ice per customer

- Cocktail Bar: 3 lbs. of ice per customer

- Salad Bar: 35 lbs. of ice per cubic foot

- Hotel: 5 lbs. of ice per room

- Healthcare: 10 lbs. of ice per patient

- Cafeteria: 1 lb. of ice per customer

How long does an ice machine last?

With proper maintenance and care, an ice maker machine typically lasts about 10 years. This can greatly lessen if you do not take proper care of your ice machine with things like regular cleaning and filter changes. For more information about taking care of your ice machine, check out our blog, Commercial Ice Machine Preventative Maintenance & Care.

What can affect my ice machine’s output?

The output listed for each ice maker machine is an estimate, but there are a few common factors that can affect your machine’s output. To ensure that your machine is functioning at full capacity, keep note of the following:

- Water Filter - keeping a water filter in your ice machine is one of the most important ways to keep your commercial ice maker machine functioning properly and producing clean ice. Most ice machine water filters should be changed at least every 6 months.

- Cleanliness - clean your industrial ice maker frequently to avoid producing any buildup or germs that can make your machine function improperly.

- Water Quality - if your potable water that flows into the industrial ice machine has large quantities of mineral deposits, the buildup it creates in the pipes can slow down the flow and in-turn slow down the ice output.

- Water Temperature - if the water flowing into the machine is too warm, it will take longer to freeze and slow down the output.

- Ventilation - if you have an air-cooled ice machine, proper ventilation is necessary to keep the machine working at full capacity. Poor ventilation makes the machine run harder and produce less ice. It is also important to ensure that your ice maker will not be directly near any hot cooking equipment, as the air going into your machine should not be too hot.

Login and Registration Form